Nissens highlights its EGR system solutions

With the environment and related issues clearly in the sights of governments around the world, there is a collective responsibility to ensure that all the internal combustion engines currently in the vehicle parc are operating to their optimum efficiency. Central to this objective is the EGR system, as it actively reduces the emissions that these engines naturally produce, keeping unwanted pollution to a minimum.

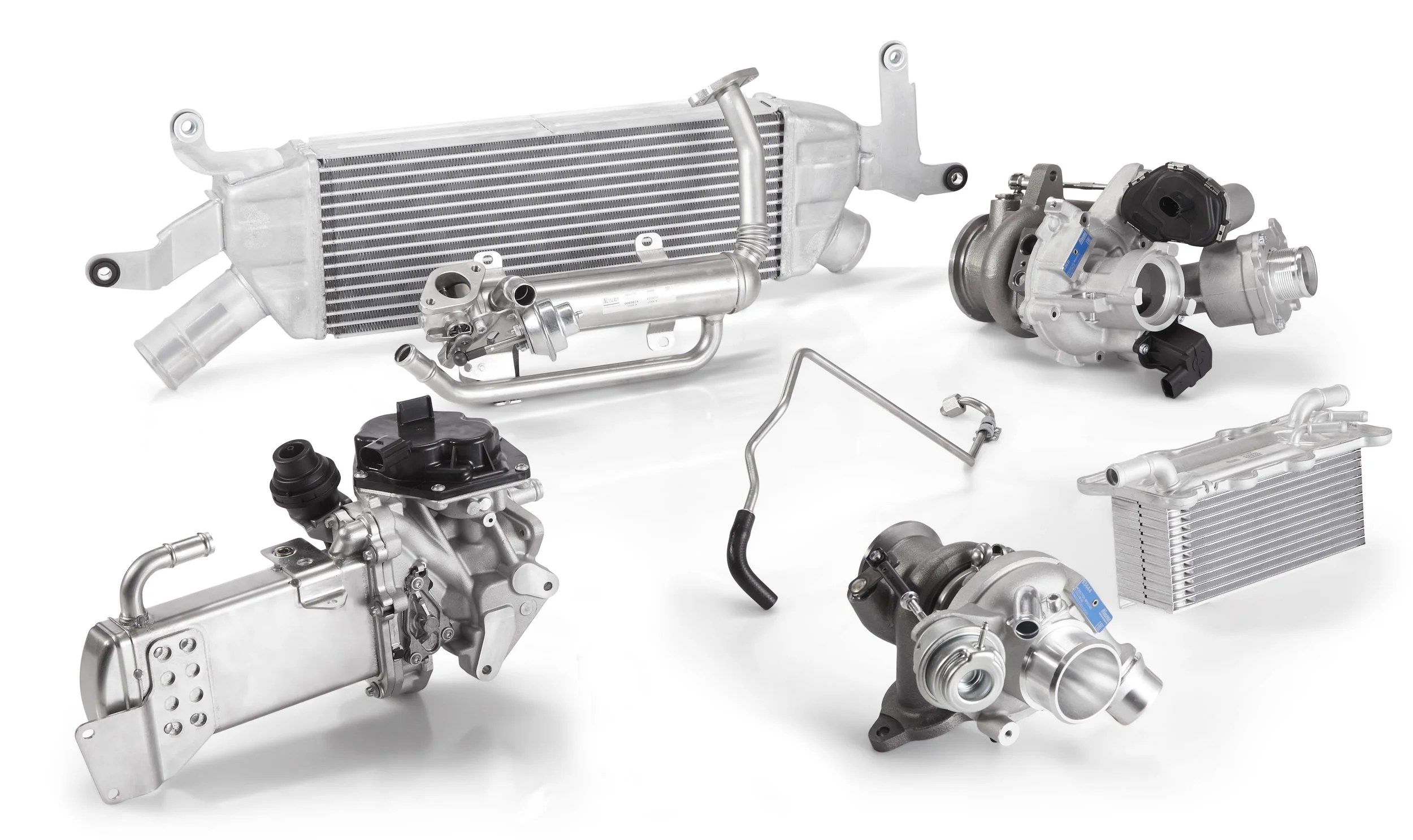

Nissens Automotive (Nissens) is a highly respected aftermarket supplier, and as part of its ongoing development strategy, the company continues to establish a solid footprint within the green automotive systems sector, which seeks to reduce the environmental impact of the internal combustion engine (ICE). It therefore offers a wide range of components within its efficiency & emissions product group, which now consists of not only EGR valves, modules and coolers, but also intercoolers, turbochargers and a throttle body offering.

EGR system related problems are increasing and a fault with the valve, for example, can lead to severe OBD errors that can result in the engine being set to limp mode and may provoke failures in other parts of the system. Common reasons for EGR system failure include unclean combustion, frequent short distance travel patterns, excessive thermal stress and moisture/contamination of the fuel.

Naturally, in common with the rest of the products in the Nissens range, all of its EGR system components are characterised by excellent product quality to allow them to conform to the company’s Genuine Nissens Quality standards. These benchmarks include undergoing a wide variety of tests, carried out both internally and externally, and incorporate many design and material improvements that contribute to their high thermal performance and overall durability.

Collectively therefore, Nissens EGR system components are premium aftermarket products that replicate the performance and fitment of the original equipment (OE) component to provide an extended, trouble-free function in the harsh conditions to which they are exposed, resulting from the frequent temperature and pressure fluctuations within the exhaust system.

A further benefit for workshop committed to complete a full and thorough repair, comes in the form of the company’s ‘First Fit’ concept, which, in common with every component in the Nissens Automotive range, means that whenever extra parts are needed for a EGR coolers’ correct installation, for example, these are automatically included in the box, making them easy to install, as well as saving professional installers time and effort in the process.

The entire Nissens Engine Efficiency & Emissions programme now encompasses EGR valves, modules and coolers, turbochargers and oil feed lines, intercoolers and a throttle body range, and consists of 1,403 individual products, catering for more than 7,600 OE part numbers and serving the majority of the European PC/LCV parc.